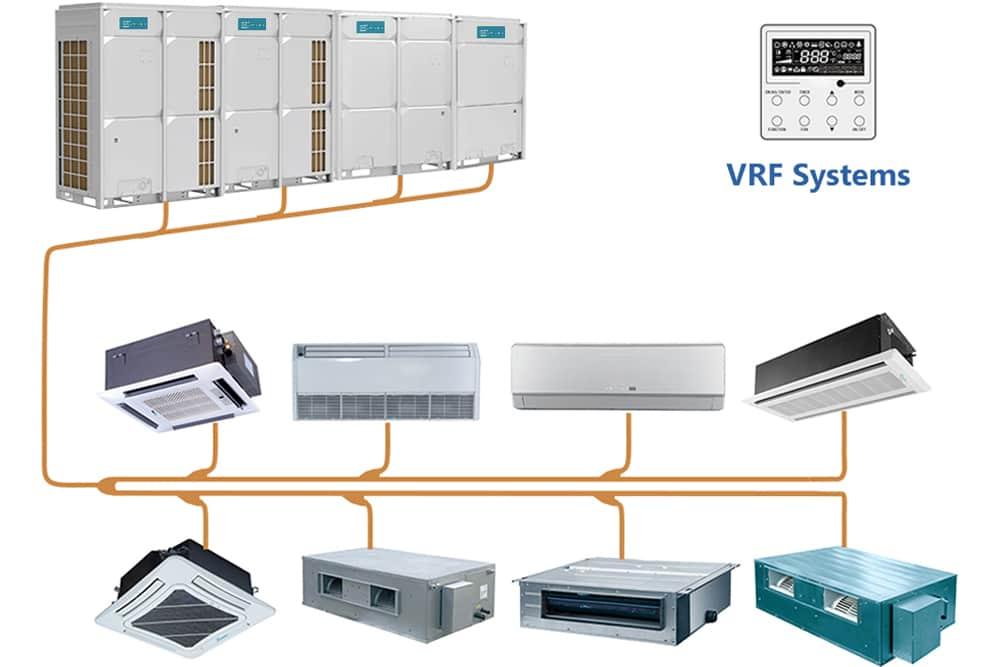

VRF-systems are universal complexes for air conditioning of large areas. Multizone VRF systems both heat and cool indoor air. On average, a conventional VRF system can operate in a room with a volume of 150-500 m2. Such systems, at an average market price, cannot provide the entire set of climatic parameters without any additional ventilation units. But they acquire such complex systems for a comprehensive solution of a global problem. Description of VRF systems - implies an individual approach to air conditioning in each room. In real time, the needs of each consumer per minute are taken into account.The VRV system is ideal for sites with indoor climates or high demand for activity. Accurate temperature control allows you to monitor changes in the VRV system and adjust its operation to economically maintain the parameters required by each user. Therefore, the VRV system is an effective complex for conditioning a particular object.

Advantages of VRV, VRF systems:

- VRV air conditioners save energy. This is possible thanks to special blocks using heat from heat. This finishing work provides for simultaneous heating and cooling of air in different rooms.

- Convenient space saver. This is achieved due to the compactness of the VRV indoor units, and the large length of the communication lines allows you to remove the external modules of the system as much as possible.

- The VRV system operates in the high temperature range. Some systems can operate at -20°C and some narrow special models can operate even at -50°C.

- Various design solutions:

- The length of pipelines increases the flexibility of system design at a given facility.

- Ability to replicate the system after commissioning.

- Possibility to replace old VRV indoor units when repairing or redevelopment of the premises.

- Phased commissioning of the system.

- The comfortable operation of the VRV is based on a control system consisting of controllers and remote controls, as well as low noise performance.

- Easy installation:

- Installation of blocks on each floor

- Commissioning the system without a commissioning phase

Chiller-fan coil systems differ from all air conditioning systems in that water (or non-freezing liquid) circulates between the indoor and outdoor units, and not freon. A chiller is a refrigeration machine designed to cool water and liquids. The chiller is a conventional freon air conditioner, through the evaporator of which water passes, and not cooled air. This water enters the fan coils through a system of insulated pipelines using a pumping station. Fancoils are installed in air-conditioned rooms and play the role of indoor units of split systems. Chiller-fan coil systems have a number of advantages over conventional multi-section or multi-zone systems:

Advantages;

- Large scale. The percentage of fans (loads) of a central cooling machine (chillers) is limited almost exclusively by its efficiency.

- Minimum volume and area. The air conditioning system of a large building may contain one chiller of minimum volume and area. The appearance of the facade is preserved due to the absence of external air conditioners.

- Unlimited distance between chillers and fan coil units. The length of the rails can reach hundreds of meters, since the specific losses of the line length meter with a large heat capacity of the liquid coolant are less than in gas cooling systems.

- Pinch value. Ordinary water pipes, shut-off valves, etc. for connecting chillers to fan coil units. use it. used. Balancing water pipes, i.e. equalizing pressure and water flow between individual fan coil units, is easier and cheaper than gas systems.

- Security. Potentially volatile gases (gas coolers) often condense in coolers installed outdoors (on the roof or directly on the ground). The risk of a pipe burst inside a building is limited by the risk of flooding, which can be reduced by using automatic shut-off valves.

Disadvantages:

Chiller-fan coil systems are not ventilation systems - they cool the air in each air-conditioned room, but do not affect air circulation in any way. However, a tubular water cooler mounted on the flow unit can be used. In one chiller, both tubular water chillers and various types of internal fan coil units can be combined, creating additional heat flows. Chiller-fan coil systems are more economical in terms of energy consumption than coating systems, but in terms of cost efficiency they certainly lose out to variable demand refrigeration (VRF) systems. However, VRF systems have a limited capacity (the volume of refrigerated rooms is up to several thousand cubic meters).

Cooler types:

- Chillers with internal air condensers and shaft fans

- Chillers with built-in air condensers and centrifugal fans

- Continuous Air Condenser Chillers

- Continuous condenser with axial fan

Modern chillers are produced in a wide range of capacities from 5 to 9000 kW, which allows air conditioning both small cottages and multi-storey buildings. All freckles can be distinguished by the following main features:

- Type of condenser cooling

- Water and air cooling

Air cooling is carried out in the same way as in household air conditioners - the condenser is filled with air flow from the fan. With water cooling, the condenser is cooled by running water. The second method helps to significantly reduce the size and cost of chili, but requires the use of running water or a slope device (circulating water pipes).

- When there is a heating mode - with or without a heat pump (reversible). Models with heat pumps not only cool the coolant, but also heat it.

- By design - with a built-in or removable capacitor. Air-cooled chillers can be monobloc (with internal condenser) or removable condenser. In the first case, the chiller is an autonomous refrigeration machine, to which only pipes from the pumping station are connected. In the second case, the capacitor is made in the form of a separate unit. This ensures that the freckles are placed inside the room and the condenser is removed from the roof. This solution simplifies the care of freckles and increases its reliability due to the constant temperature in the room.Also, since the chiller itself and all heat-carrying pipes are indoors, the use of anti-freeze liquid can be avoided, and water can be used as a heat carrier without being pumped out in winter.

- Air-cooled monobloc chillers can be equipped with axial or centrifugal fans. Axis fans are cheaper but create less air pressure. Therefore, chillers with axial fans are installed only in open areas - on the roof, on the walls of a building, etc. can be placed. Centrifugal fans create stronger air pressure. Therefore, coolers with such fans can be placed indoors, allowing air to escape through the fence and duct. In addition to conventional freon chillers, absorption chillers are also available. In such refrigerants, water and an absorbent (lithium bromide) are used instead of freon. The circulation of absorption cooling is similar to freon.During the transition of heat from a vaporous state to a liquid state, the effect of its absorption by the refrigerant is used. During the operation of absorption chillers, the following occurs: under the influence of an external heat source (gas burner, steam or hot water), refrigerant (water) vapors are released from a concentrated solution of lithium bromide, which are carried to the condenser. Here they condense into liquid entering the evaporator. The water evaporates in the evaporator and its vapors are absorbed by the absorbent sweat (concentrated lithium bromide solution). The stirred absorbent solution is then heated and the whole cycle is repeated. It is the energy source for hot water or steam absorption chillers.Therefore, they are often used where there are severe restrictions on the electricity used. Absorption chillers are not common in Russia due to the underdevelopment of energy storage technologies. These freckles are usually

- Multi-split air conditioners are made up of many parts. In a cooling system, indoor units are connected to one outdoor unit. Thus, difficulties and visual pollution in the area formed by the outer blocks can be prevented.

- Multi-split air conditioners are available in various indoor unit options such as wall-mounted, indoor, floor-to-ceiling. In addition, there are 8 models of multi-split air conditioners with an indoor unit connected to an indoor unit. Each built-in module can be controlled independently from each other.

Multi split air conditioners are used:

- In homes and workplaces

- in stores

- in shopping centers

- school

- in hospitals

- In conference rooms and concert halls

Multi differs from other systems in air conditioning functions. It provides excellent performance with detailed control, multiple control systems at the same time, design flexibility, easy installation and maintenance, silent operation system, high energy saving and single central control.

Istec Engineering offers professional services for the design, installation and maintenance of refrigeration systems. We can design and offer many types and brands of air conditioners according to customer needs. First of all, they depend on the purpose, size and budget of the object provided by the customer. In any case, our company gives a full guarantee for the product installed by it and carries out regular maintenance of the systems installed by us. Our main goal is to create comfortable living conditions for the owner of a large or medium-sized business or a client who owns a house.

The systems we offer to our customers are based on flexibility in installation, use of advanced technology, high quality and maximum energy savings in cooling and heating, year-round operation. Through cooperation with our partners, we offer you a wide range of air conditioning, VRV, VRF and Chiller-Fancoil systems.